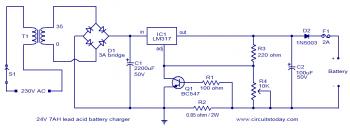

This circuit is a current limited lead acid battery charger built around the famous variable voltage regulator IC LM 317. The charging current depends on the value of resistor R2 and here it is set to be 700mA. Resistor R3 and POT R4 determines the charging voltage. Transformer T1 steps down the mains voltage and bridge D1 does the job of rectification. C1 is the filter capacitor. Diode D1 prevents the reverse flow of current from the battery when charger is switched OFF or when mains power is not available.

The schematic diagram:

Source: http://www.circuitstoday.com/24v-lead-acid-battery-charger-circuit

The schematic diagram:

Circuit Notes:

- Assemble the circuit on a good quality PCB.

- F1 can be a 2A fuse.

- T1 can be a 230V primary, 35V/3A secondary step down transformer.

- LM317 must be fitted with a heat sink.

- If 3A Bridge is not available, make one using four 1N5003 diodes.

- R2 = 0.85 ohm is not a standard value. You can obtain it by combining a 6.2 ohm and 1 ohm resistors in parallel.

- To setup the charging voltage, power ON the charger and hook up a voltmeter across the output terminals and adjust R4 to make the voltmeter read 28V. Now the charger is ready and you can connect the batteries.

- This battery charger is specifically designed for two 12V/7AH/6 cell lead acid batteries in series OR a 24V/7AH/12 cell lead acid battery.

Source: http://www.circuitstoday.com/24v-lead-acid-battery-charger-circuit

Comments