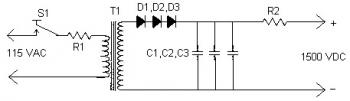

This is a very simple high voltage power supply circuit for laser device. It is low cost circuit and very easy to built. This power supply can be built with common parts, most of which you probably already have in your junk box. The secret of this circuit is the transformer used. It is a common 9V 1A transformer unit, connected backwards for step up. Please note that some people may have trouble with this supply. This is due to the slight difference in transformers.

Parts List:

R1 = 10 Ohm 10W Or Greater Resistor

R2 = Ballast Resistor, read the notes

D1, D2, D3 = 1N4007 Silicon Diode

C1, C2, C3 = 0.1 uF / 2000V Capacitor

T1 = 9V 1A Transformer

S1 = 115V 2A SPST Switch

MISC = Case, Wire, Binding Posts (for output), Line Cord

Circuit Notes:

- T1 is an ordinary 9V 1A transformer connected backwards for step up.

- R1 MUST be installed on a LARGE heatsink. A good heatsink is the metal case the power supply is built in.

- R2 secures the laser tube from excess current. It should be soldered directly to the anode terminal on the tube. To find R2, start with a 500K 10W resistor and work down until the tube lights and remains stable.

- If you have trouble with the tube not starting easily, use a longer anode lead that is wrapped around the tube.

- Depending on the transformer you use, the circuit may or may not work. Build at your own risk. Some transformers consist of very few secondary windings which will quickly saturate the core and basically act like a direct short. The more secondary windings (that is, primary in this circuit) the better.

Simple power supply circuit for laser, source page: http://www.aaroncake.net/circuits/lasersup.asp

Comments